Why to use anti aging for plastic?

- Why should use anti-aging for plastic?

Plastic material is becoming increasingly essential in life, with the development of the technology of machining, plastic has been applied and gradually replace the material such as glass, metal, paper, and wood.

Conventional plastic is made from the polymerization reaction and condensation, form the high-molecular compound. In the process of impact by agents: temperature, radiation, light, mechanical stress,..., water, air, chemicals... will transform the structure leads to the change of molecular weight of the resin.

In which the factors that impact plastic, through the process of combining with oxygen radicals do one of the cause of degeneration to plastic, collectively referred to this process is the aging process plastic. Plastic aging will be as fast if impact-resistant at the same time by the other disadvantage such as temperature, radiation,... and for plastic:

- Deterioration of physical and mechanical properties, losing malleability and tolerance power.

- Rift create chalk surface.

- Color fade, lose color, turn blue,...

High quality granny is component additive helps reduce the process of aging process on, that is why you should use quality aging, especially for those products long-term use.

- Classification of anti-aging:

There are several classifications of the high resistance aging, but in a simple way can be classified according to their application, which is: High aging resistance used in machining and high resistance to aging activity in the conditions of use.

– High aging resistance used in machining: Is the component used to help protect the plastic from the effects of free radicals in the machining process, at a temperature and high stress.

– Anti-aging activity in normal temperature: 's active ingredients at low temperature, ambient temperature, helps to protect the resin from the original oxidation, derived from the oxygen in the air, or born from the result of mechanical impacts, radiation,...

- High aging resistance use in:

Conventional plastic is supplied as granules, powder. Through the process of machining, plastic variable morphology (flow) under the action of mechanical energy and heat energy so that the structure analysis of plastic is strong in impact.

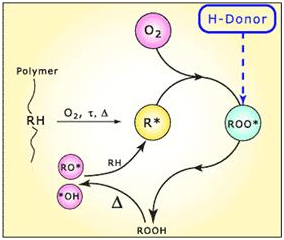

The high stable machining is the high room oxidant is added to the asphalt mixture to stop the degenerative process while machining. High stable machining this prevents the reaction oxidation in plastic, helps neutralize free radicals (R*, ROO*,...) has formed in the mixture.

Disabling the radicals have helped prevent the chain reaction are unfavorable, should limit the variation properties of plastic.

Under the adverse effects of the energy source or the last high, the associated poor durability of plastic will be fracturing the formation of free radicals. The free radicals on will continue to impact on the link adjacent birth to the new reactions, forming the free radical new development and release chain reaction spontaneously.

- Stabilizer system Phenolic (H_donor)

Compound H-donor reaction with free radicals, peroxy (ROO*), and prevents the process of obtaining the element Hydrogen on the circuit molecules plastic, turning them into the hydroperoxide.